Hi there,

I’d like to discuss the idea of a 24V bus line that @divsys gave me a few weeks ago on discord issue chat (6.10.23, 00.08).

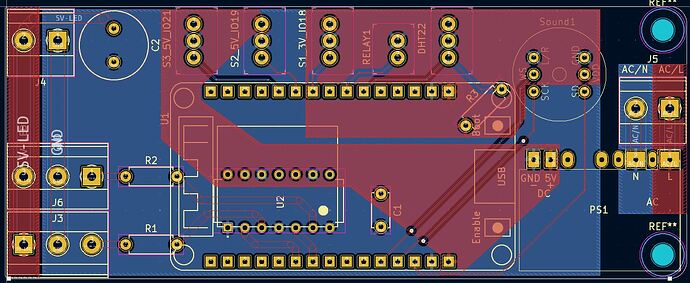

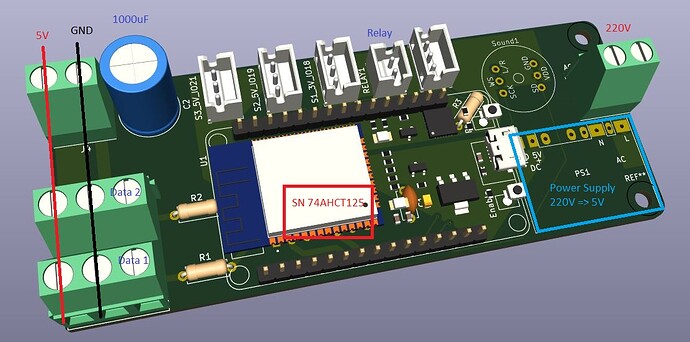

My project is about indirect light between ceiling and wall. I’d like to install that in every room of my house, so I installed a cable canal (6x4cm) around every room (between ceiling and wall), sk6812-strip (60led/m, 5V) is glued to aluminium profile. The question is/was, how do I provide power and how to inject it, 8m is a minimum of length (1 wled controller), 1 room has something between 30-35m (3-4 controllers). In every edge and further every 2-2,5m (max. alu profile length) I have an injection point either way.

My idea was to put small power supplies like this:

https://www.reichelt.de/led-trafo-40-w-5-v-dc-8000-ma-mw-lpv-60-5-p185799.html

…in cable canal at every injection point. In cable canal runs a 230V-cable which shall be shut off by a relay controlled by wled. First problem was the very high inrush current, relay was damaged several times, even the fuse was blown out some time. I solved that by using industrial relay like this:

https://de.aliexpress.com/item/1005005757882881.html?spm=a2g0o.order_list.order_list_main.16.28105c5fcQ6JTV&gatewayAdapt=glo2deu

…and a inrush limiter like this:

https://www.reichelt.de/einschaltstrombegrenzer-lineare-bauform-16-a-icl-16l-p306701.html

My test installation with 5 power works fine, but has a flash when I turn on light via browser or app. I solved this by using preset/playlist-workaround, but I cannot use this via gui.

Adding a 1000uF capacitor to power line which is recommended here:

https://kno.wled.ge/basics/getting-started/

didn’t make the flash at turn on disappear. It must be something with my power supplies, especially if I get too much of them, 2 power supplies didn’t make that flash.

In this video is said, that you cannot or shouldn’t connect + line of different power supplies. Maybe that is the problem.

I discussed all that in discord issues channel from 5.10.23 11:33 on, some of the experts tried to help me (@blazoncek, @Quindor, @divsys …).

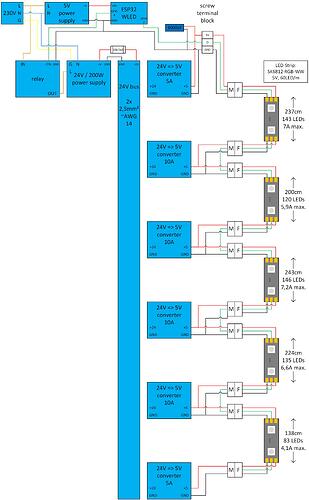

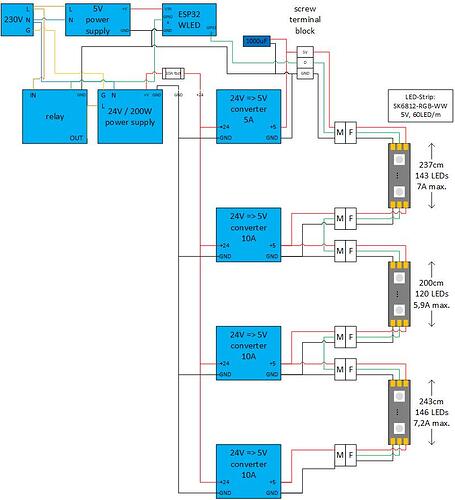

Now comes the idea of @divsys with 24V bus line, which I could use instead of my “power supplies at every injection point” solution. A big 24V power supply at the beginning starts a 24V line, which goes inside cable canal along all the way with the led strip and 24V-to-5V-converter provides the 5V at every injection point.

I have some questions about this 24V line. Maybe someone (e.g. @divsys himself ![]() ) has the answers or further suggestions.

) has the answers or further suggestions.

It was said, that voltage drop isn’t a problem. What if I have a strip with 13m or more (15m, 20m) and I “take power” every 2-2.5 meters, won’t the voltage drop be very bad?

How about safety: what fuse have I to take and where to put it? At every injection point or right after power supply at beginning of 24v bus line?

Is this the right converter?

https://de.aliexpress.com/item/4001107349411.html?spm=a2g0o.cart.0.0.55c44ae4oekzK5&mp=1&gatewayAdapt=glo2deu

Is this 24v-bus-line solution scaleable or which limits are there. Does this work?

20m=>1200leds=>300W (60A@5V) or even more?